Introduction

Cleaning

and maintenance of the carburetor

The most

frequent break downs come from the pollution of the

carburetor by dirt from the fuel or from sucked in air. Depending the

environment, in which the motorcycle is driven, the time schedule is to

be selected, in which the carburetor is cleaned. Other disturbances do

not arise with the carburetor. If the throttle valve should wobble,

then it became loose and must be replaced against a new one. If the

throttle valve abrasive itself in, the mixing chamber must be honed.

Usually with to strong pressure on the needle perforated

floats must be replaced or after drying soldered. The leakage of the

float needle in its seat in the float frame cover is eliminated by

grinding in with abrasive paste or by replacement of the components.

Cleaning the carburetor must be done off the machine, for which the

two door halves of the front lining must be opened (fig. 1).

The most

frequent break downs come from the pollution of the

carburetor by dirt from the fuel or from sucked in air. Depending the

environment, in which the motorcycle is driven, the time schedule is to

be selected, in which the carburetor is cleaned. Other disturbances do

not arise with the carburetor. If the throttle valve should wobble,

then it became loose and must be replaced against a new one. If the

throttle valve abrasive itself in, the mixing chamber must be honed.

Usually with to strong pressure on the needle perforated

floats must be replaced or after drying soldered. The leakage of the

float needle in its seat in the float frame cover is eliminated by

grinding in with abrasive paste or by replacement of the components.

Cleaning the carburetor must be done off the machine, for which the

two door halves of the front lining must be opened (fig. 1).

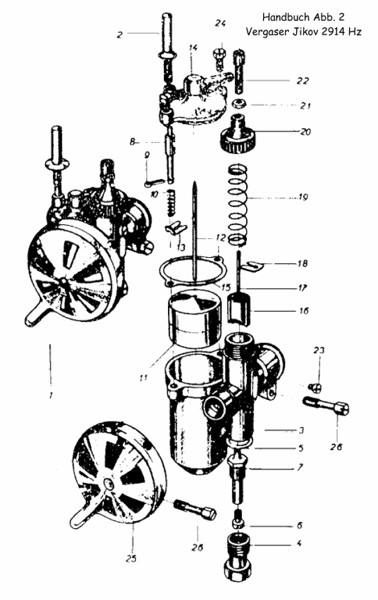

Carburetor

JIKOV 2914 Hz (fig. 2); (

parts catalog carburetor ).

This

type is used with the machine Jawa 50, type 555. The Fuel valve is

locked off and the fuel rubber hose is removed. By opening the fuel

valve is the control that the fuel inlet from the tank is not

clogged. If this is the case, the valve must dismantled and the

fuel strainer cleaned. The nut of the mixing chamber (20) and the guide

screw (23) are loosened and the fuel valve (16) is taken out

including the nozzle needle (17) adjusted according to work regulation

by means of the safety device (18) in the second needle cut from above.

Then the screw (26) is loosened and the carburetor is removed from the

motor. With the same screw the filter is fastened as well, always the

filter is to

be cleaned in gasoline. Take care that always first the

carburetor parts are rinsed in the gasoline and then the dirty

filters, whose efficiency can be increased by rinsing it with a

thin oil film. The needle jet (6) is accessible after

loosening of the screw (4). The correct caliper of the nozzle is the

number 65. The two screws (24) are unscrewed and the float house cover

(14) is removed, whereby damage of the seal is to be

avoided (15). After removal of the float (l1) the entrance to its

needle

(12) secured by the safety device (13) is free. If the fuel valve

(16) must be dismantled, the spring(19) is slightly pressed in and the

gas cable is taken out of its cut. The

assembly takes place in reverse.

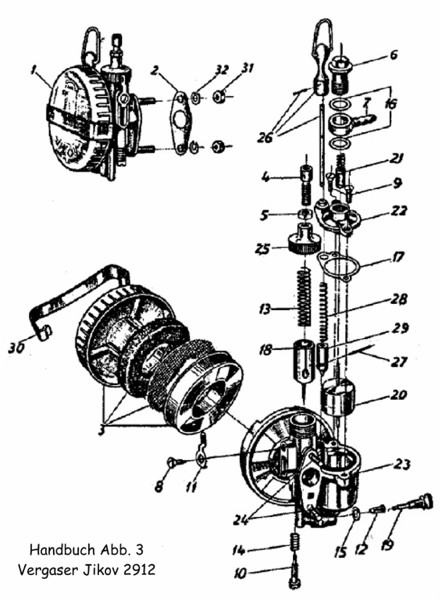

Carburetor

Jikov 2912 (fig. 3)

This carburetor was used

with the Jawa 50, type

550.

After separating the

fuel hose from the tank

and after control of the fuel streaming, proceed

as follows: The nut of the mixing chamber (25) and the guide

screw (8) are loosened and the fuel valve (18)

is taken out.

The carburetor is dismantled from the motor. The noise damping air

filter is removed likewise and cleaned after shifting the clamp spring

(30). The fuel flush mouthpiece onto the floating chamber

(7) is also cleaned, after loosening of the nut. The strainer is

to be flushed as well. The floating chamber is dismantled after

loosening the two screws (19), its cover (22) and seal (17) is

removed and the floater including the needle (20) is taken out. After

unscrewing the screw (19) provided with the seal (15) the entrance to

the main jet (19) is free. All components are rinsed and the

assembly of the carburetor and the filter is accomplished in reversed

order. The gas cable is taken from the cut in the throttle lever after

pressing the spring

slightly. The cable play is adjusted by the screw (4) and the locknut

(5). By assembling the carburetor on

the motor may not be forgotten to install the the seal.

< >